Ultrasonic Pulse Velocity

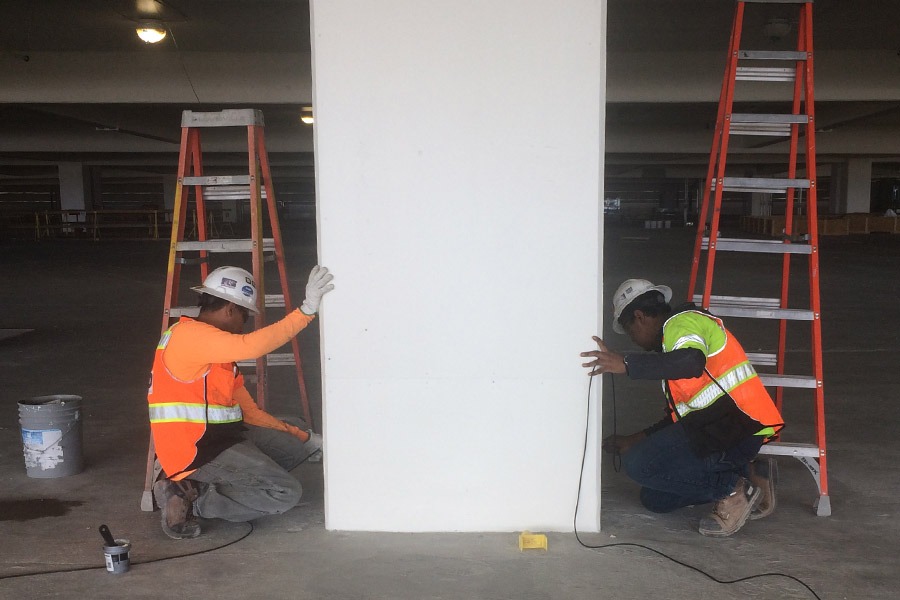

Ultrasonic Pulse Velocity (UPV) investigations are performed to assess the condition of structural members if access to both sides is available.

Sonic Pulse Velocity (SPV) is performed on mass concrete over 10 ft (3 m) thick.

The Ultrasonic Pulse Velocity (UPV) systems are designed to identify and map voids, honeycomb, cracks, delaminations, and other damage in concrete, wood, masonry, stone, ceramics, and metal materials. UPV tests are also performed to predict strength of early age concrete. The UPV methodology relies on direct arrival of compressional waves.

The test is performed by positioning the source and receiver on either side of the area in question, then the source sends a compressional wave through the region, and the receiver records the full waveform on the other side. The position of the two transducers can be varied such that direct, semi-direct, and indirect tests can be performed, which aids in mapping out the volume of the defect. Further tests can be performed if the user wishes to generate a 3-D rendering of the volume in question. This is done by testing many different “paths” through the medium and then using Tomographic Imaging Software, which is sold by Olson Instruments. (Note: Optional Tomo software is available for the CSL, UPV, and CS/DS add-on test methods.)

Data Platform Required, Sold Separately

|

Freedom Data PC |

|

NDE 360 |

UPV Case Study

Materials Tested:

- Beams

- Bridge Decks

- Elevated Slabs

- Shaft Tops

- Walls

Test For:

- Cracks

- Delaminations

- Honeycomb

- Velocity vs Strength Correlation with Cores

- Voids

Meets ASTM:

- ASTM C597-02

- E494-95

- BSI 98/105795

Meets ACI:

- 228.2R

Key Features & Specifications

| Short learning curve for data acquisition and basic processing | Waterproof in shallow water ~ 50 KHz UPV transducers standard |

| System is compact, durable, and easily transported allowing for multiple tests per day | 2-D maps are easily generated from data by exporting the tables from Olson's WinUPV Software into Excel |

| Using optional Tomographic Imaging Software, images can be generated from acquired data giving the user a 2-D or 3-D visual tool of the region in question | English or Metric units can be used |

| Ultrasonic Source and Receiver Transducers are fully interchangeable | Real-time waveform display while testing |

UPV-1 Model

| Description: | Test For: | Applicable On: |

| The UPV-1 is the base model system for testing compression wave velocity and flaw detection. System designed to test a variety of "paths" through a medium and then create 2-D contour maps by importing the results table into popular spreadsheet programs.Download System Overview PDF |

|

|

SPV-1 Model

| Description: | Test For: | Applicable On: |

| The SPV-1 is comprised of a 0.2 lb (0.1 Kg) instrumented impulse hammer and accelerometer receiver to test mass concrete up to 20 ft (6 m) in thickness. |

|

|

SPV-2 Model

| Description: | Test For: | Applicable On: |

| The SPV-2 is comprised of a pair of accelerometer receivers to test mass concrete up to 20 ft (6 m) in thickness. |

|

|

TOMO-1 Software [Optional]

| Description: | Test For: | Applicable On: |

| Ultrasonic Pulse Velocity (UPV) Tomograms are generally used to map out the location, extent, and severity of defects in structural members. This method takes advantage of the multiple crossing test paths generated by combining direct, semi-direct, and indirect UPV testing. This data, once picked for First Arrival Time (FAT), is used to generate 2-D or 3-D velocity images.

These images can often be a valuable resource when repairs are needed on structural members because it provides the information necessary to isolate the problem. Sonic Pulse Velocity (SPV) data is used to provide velocity images of massive dams, bridge substructures, etc. |

|

|

Hands-on training is available for all of our NDE test methods at our Wheat Ridge, Colorado (USA) location, which is a suburb located approximately 15 minutes northwest of downtown Denver. Training may be available at your location by one of our agents/engineers upon special arrangement.